Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

The development trend of custom machining center

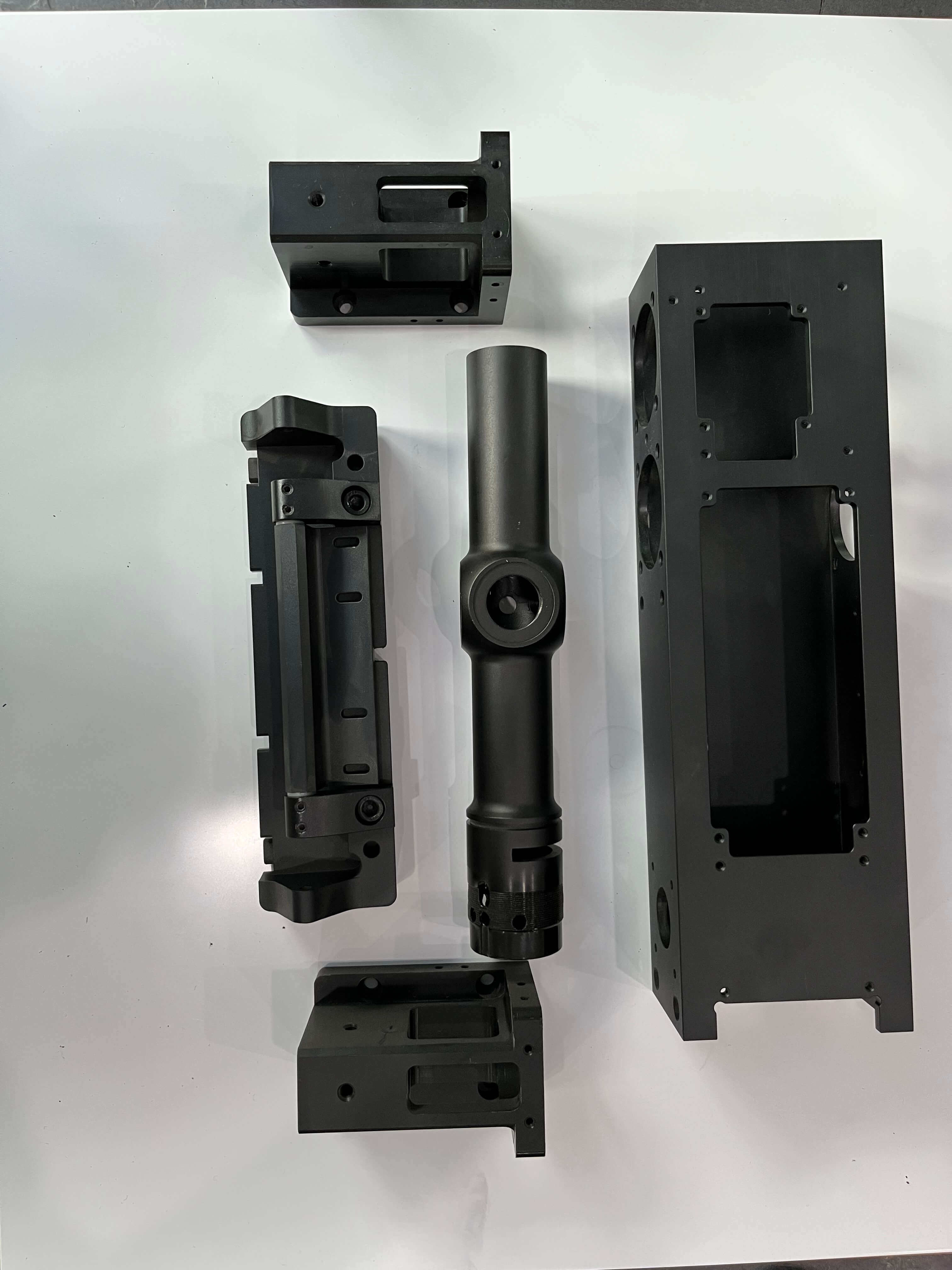

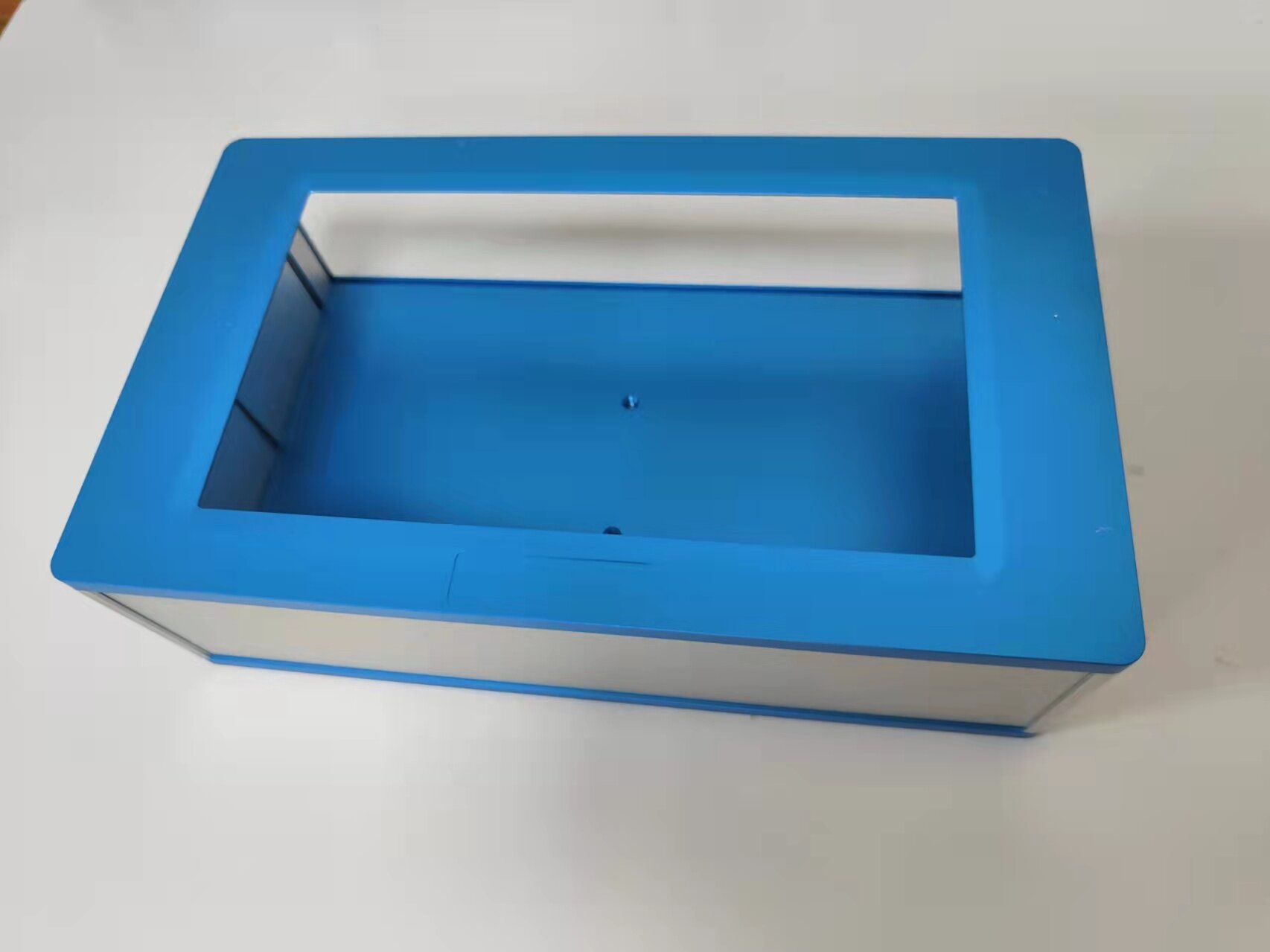

Custom machining center is a high-efficiency automatic machine tool composed of mechanical equipment and numerical control system suitable for processing complex parts. It concentrates the functions of milling, boring, drilling, tapping and thread cutting on one equipment, making it have a variety of technological means.

With the continuous development of the world's advanced manufacturing technology and the application of ultra-high-speed cutting, ultra-precision machining and other technologies, Rou has put forward higher requirements for CNC machining technology. The future custom machining center will develop towards the following trends:

All kinds of custom machining centers equipped with automatic tool changing mechanism can realize milling, boring, drilling, turning, reaming, reaming, tapping and other processes at the same time on the same machine tool.

The custom machining center also adopts multi-spindle and polyhedron cutting, that is, different parts of a part are cut in different ways at the same time.

In order to meet the requirements of flexible manufacturing systems and computer integrated systems, the CNC system has a long-distance serial interface, and can even be networked to realize data communication between machining centers, and can also directly control multiple CNC milling machines.

Speed and precision are two important indicators of data processing centers, which are directly related to processing efficiency and product quality. At present, the numerical control system adopts a processor with a higher number of digits and a higher frequency to improve the basic operation speed of the system.

The custom machining center will also adopt the structure that the spindle motor and the machine tool spindle are combined into one, realizing the integration of the frequency conversion motor and the machine tool spindle. The bearing of the spindle motor adopts the form of magnetic bearing, hydrodynamic and static pressure bearing or ceramic rolling bearing.

Modern CNC milling machines will introduce adaptive control technology to automatically adjust working parameters according to changes in cutting conditions, so that the best working state can be maintained during the machining process, so as to obtain higher machining accuracy and smaller surface roughness. Improve tool life and equipment productivity.

In the whole working state, the system conducts self-diagnosis and inspection of various equipment connected to it at any time. Once a fault occurs, measures such as shutdown are immediately taken, and a fault alarm is performed to indicate the location and cause of the fault. In order to achieve higher fault diagnosis requirements, the development trend of custom machining centers is to use artificial intelligence expert diagnosis systems.

At present, the models of custom machining centers are different, and the machining tools and lubrication systems are also different.

In the future, with the continuous progress of the autonomous processing of custom machining centers, the processing tools will also tend to be standardized.

The custom machining center only needs to replace the standard tools according to its own needs to complete the process. The matching lubrication system will automatically cut the metalworking oil used in different processes to meet the process requirements.

The miniaturization of the numerical control system facilitates the integration of the mechanical and electrical devices. At present, ultra-large-scale integrated components and multi-layer printed circuit boards are mainly used, and three-dimensional installation methods are adopted to enable high-density installation of electronic components and reduce the occupied space of the system on a large scale.

The use of a new type of color liquid crystal thin display will further miniaturize the numerical control operating system. In this way, it can be easily installed on the machine tool, which is more convenient for the operation of the custom machining center.

In the End

The above is the future development trend of custom machining center. With the continuous improvement of the industrial level, new industrial technologies are also emerging in the future. If you want to buy custom machining center, welcome to contact us.